Comparison between Sodium-ion Batteries and Lithium-ion Batteries

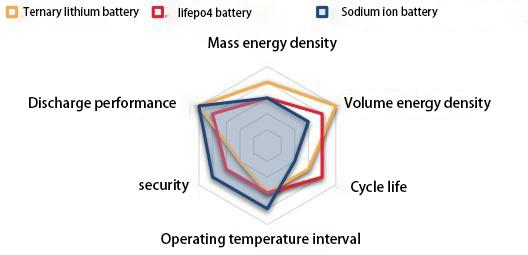

There are differences in the physicochemical properties of sodium and lithium, which result in distinct electrochemical performance characteristics between the two.

The larger mass and radius of sodium ions lead to a slower migration rate in sodium storage materials, which is not conducive to improving the rate performance of sodium-ion batteries. This also results in the energy density (mass/volume) of sodium-ion batteries being lower than that of lithium-ion batteries.

For instance, the Kirin Battery (a lithium-ion battery) released by CATL has an energy density of up to 255Wh/kg, whereas the energy density of sodium-ion batteries is only 160Wh/kg. This significant gap is partly due to the fact that sodium-ion battery technology is not as mature as lithium-ion technology. Additionally, the inherent properties of sodium mean that the energy density ceiling for sodium-ion batteries will be lower than that of lithium-ion batteries.

Currently, the energy density of sodium-ion batteries overlaps partially with that of lithium iron phosphate batteries, while there is a more considerable difference compared to ternary lithium batteries.

Comparison of Performance Parameters between Lithium-ion Batteries and Sodium-ion Batteries

|

Category |

Sodium-ion Battery |

Lithium Iron Phosphate Battery |

Ternary Lithium Battery |

Energy Density (Wh/kg)

|

100~150 |

120~160 |

200~300 |

Energy Conversion Efficiency

|

84~90% |

86~90% |

88~90% |

Cycle Life (times)

|

2000~5000 |

3000~6000 |

800~1500 |

Response Speed

|

<10ms |

<10ms |

<10ms |

|

Safety |

Moderate |

Moderate |

Poor |

Initial Investment Cost (Yuan/Wh)

|

1.1~1.4 |

1.5~2 |

1.8~2.5 |

Full Lifecycle Cost of Electricity (Yuan/kWh)

|

0.6~0.8 |

0.56~0.75 |

1.2~2 |

Environmental Friendliness

|

Good |

Moderate |

Moderate |

Under these circumstances, sodium-ion batteries require different material systems to adapt to their unique physicochemical properties and maximize the advantages of sodium ions. Therefore, there are differences in the selection of cathode and anode materials, electrolytes, and current collector materials between the two types of batteries.

Comparison of Materials between Lithium-ion Batteries and Sodium-ion Batteries

|

Type |

Lithium-ion Battery |

Sodium-ion Battery |

Cathode Material

|

Ternary materials, lithium iron phosphate, lithium

manganese oxide, etc. |

Layered oxides, Prussian blue,

polyanions, etc.

|

Anode Material

|

Graphite |

Amorphous carbon

|

Electrolyte

|

Lithium hexafluorophosphate

|

Sodium hexafluorophosphate

|

Cathode Current

Collector

|

Aluminum foil

|

Aluminum foil

|

Anode Current

Collector

|

Copper foil

|

Aluminum foil

|

Separator

|

PP/PE |

PP/PE |

Based on the performance comparison, sodium-ion batteries perform worse in terms of energy density and cycle life. However, they have clear advantages in terms of cost-effectiveness, safety, and temperature adaptability.

Especially in terms of safety, sodium-ion batteries excel. According to testing by the China Automotive Technology and Research Center Co., Ltd. (CATARC), sodium-ion batteries do not emit smoke, ignite, or explode when punctured. They also pass safety tests for short circuits, overcharging, over-discharging, and compression without catching fire, showing significantly better safety than lithium-ion batteries.

Additionally, sodium-ion batteries have superior thermal stability. The onset self-heating temperature for lithium-ion batteries is 165°C, whereas for sodium-ion batteries, it reaches 260°C. In ARC testing, the maximum self-heating rate of sodium-ion batteries is also significantly lower than that of lithium-ion batteries. In all current safety tests, sodium-ion batteries have shown no incidents of fire.

The greater safety of sodium-ion batteries compared to lithium-ion batteries is primarily due to sodium’s position as the next element in the periodic table after lithium, giving it more stable chemical properties. Sodium-ion batteries also have a higher internal resistance than lithium-ion batteries, resulting in less instantaneous heat generation in short-circuit and other safety tests. Furthermore, sodium-ion batteries use a more stable aluminum foil as the anode current collector and can be fully discharged to 0V for transportation, enhancing their transport safety.

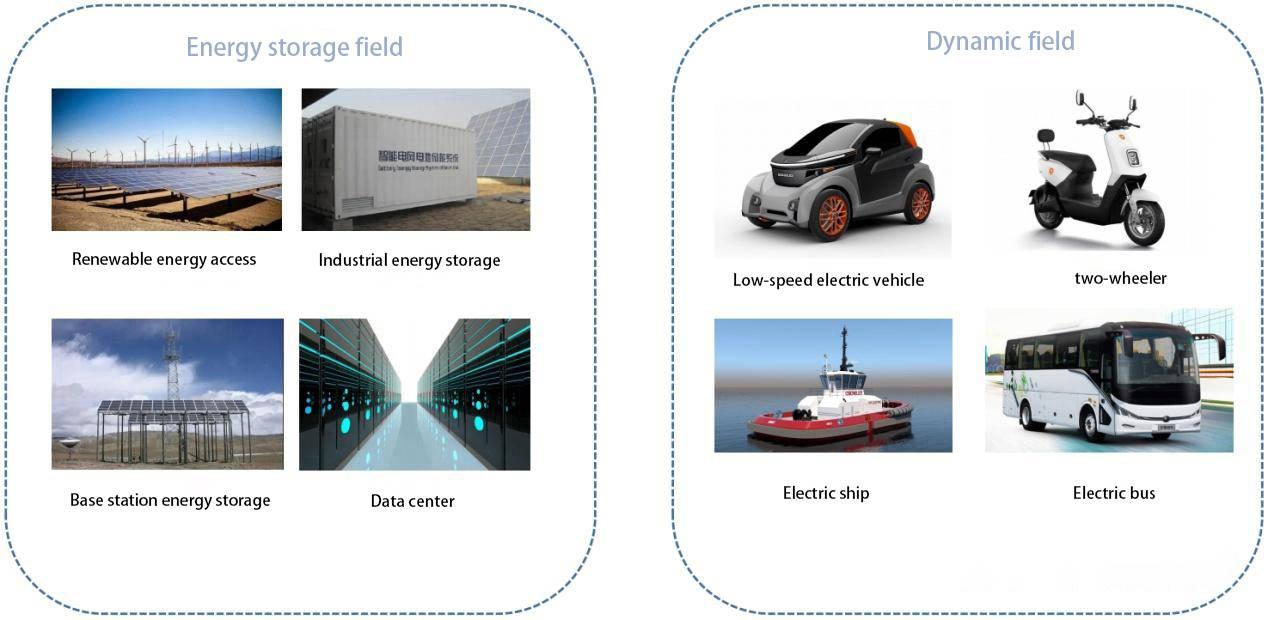

Application Fields

Sodium-ion batteries have their unique advantages, but they have not yet been mass-produced on a large scale, making it difficult to reduce costs. As technology matures over time, their cost advantages are expected to become more apparent, leading to widespread application in areas such as energy storage, electric bicycles, and low-speed electric vehicles (including low-speed four-wheelers and electric tricycles).

1. Energy Storage Field

The cost per kilowatt-hour for lithium iron phosphate batteries and ternary lithium batteries is relatively high, making it difficult to meet the requirements for large-scale commercialization in capacity-type energy storage. For energy storage, the ideal cost per kilowatt-hour needs to be below 0.3 yuan/kWh, making sodium-ion batteries the most promising candidate for application.

2. Electric Bicycle Field

Currently, the number of electric bicycles in China has reached 320 million, with 70% to 80% of them using lead-acid batteries.

Lead-acid batteries are the most mature in terms of industrialization but face serious environmental issues. Used lead-acid batteries contain substances like lead and lead-acid liquid that severely pollute the environment. In terms of performance, lead-acid batteries fall short compared to lithium and sodium batteries in both cycle life and energy density.

To further regulate the industry, China implemented the "Electric Bicycle Safety Technical Specification" (referred to as the "New National Standard") on April 15, 2019, which stipulates that the total weight of electric bicycles (including the battery) should not exceed 55 kg.

Due to their low energy density, more lead-acid batteries are needed to increase range. For example, if an electric bicycle requires 1 kWh (approximately 75 km range), the lead-acid battery would weigh 25 kg. As a result, electric bicycles using lead-acid batteries often exceed 70 kg and do not meet the "New National Standard," whereas lithium batteries under similar conditions weigh only 5 kg.

Given the requirements for battery volume and weight, low-energy-density batteries like vanadium batteries (15~50 Wh/kg) are excluded, leaving lithium-ion and sodium-ion batteries as the main contenders.

With the push from the "New National Standard" policy and upgraded consumer demand, lithium batteries are rapidly replacing lead-acid batteries, with their penetration rate in two-wheel electric vehicles reaching 23.4% in 2021.

Since 2021, the prices of upstream raw materials for lithium batteries have risen sharply, driving up costs and increasing the purchase price for consumers. Additionally, lithium batteries often experience reduced range during winter.

This situation creates an opportunity for sodium-ion batteries.

Compared to lithium-ion batteries, sodium-ion batteries have lower costs, a wider operating temperature range, higher safety, and the energy density requirements for electric bicycles are not as high as for electric cars. Therefore, sodium-ion batteries are expected to be rapidly adopted in electric bicycles.

At the end of 2017, HiNa Battery developed a 48V/10Ah sodium-ion battery pack for electric bicycles. In July 2021, Aima Technology announced the world's first batch of sodium-ion battery-powered electric bicycles at a dealer conference, marking the transition from demonstration to mass production.

Sodium-ion batteries have a cycle life far exceeding that of lead-acid batteries, an energy density more than three times higher, and a significantly lower cost. With the involvement of leading companies, the application of sodium-ion batteries in electric bicycles is expected to accelerate.

3. Low-Speed Electric Vehicles and A00-Class Electric Vehicles

Low-speed electric vehicles are known as "national cars" as drivers do not need a license, nor do they need to pay for license plates or insurance fees, making them popular in third- and fourth-tier cities and rural areas in China.

Due to their advantage in initial cost, most low-speed electric vehicles in China previously used lead-acid batteries, but replacement is inevitable.

To regulate industry development, the Ministry of Industry and Information Technology released the "Technical Conditions for Pure Electric Passenger Vehicles" draft for comments in June 2021. The draft specifies that four-wheeled low-speed electric vehicles will be classified as a subcategory of pure electric passenger vehicles, named "micro low-speed pure electric vehicles," and sets out relevant technical indicators and requirements, formally incorporating low-speed electric vehicles into standardized management.

With the standards defined, many automakers have targeted the low-speed electric vehicle market and introduced low-cost A00-class electric vehicles. The Wuling Hongguang MINI EV, as a representative of A00-class pure electric vehicles, has topped the monthly sales charts for new energy vehicles for several consecutive months.

Low-speed vehicles and A00-class electric vehicles are mainly used in rural and urban areas for school pickups, short shopping trips, and other short-distance commuting needs. The range requirements are not high, and the energy density requirements for power batteries are relatively lower. In 2018, HiNa Battery launched the world's first sodium-ion battery-powered low-speed electric vehicle (72V, 80Ah), opening up application space for sodium-ion batteries in the electric vehicle field.

The low price of A00-class electric vehicles and the high proportion of battery costs make them more sensitive to battery pricing. With its cost advantages, sodium-ion batteries are expected to thrive in this area.

Company Deployment

Companies involved in sodium-ion battery development domestically can be divided into two main categories: the first category consists of companies with backgrounds in universities and research institutes, focusing on the research and development of sodium-ion batteries and having developed relatively mature technologies. For example, HiNa Battery’s technology originates from the Institute of Physics at the Chinese Academy of Sciences, while the core team of Sodium Innovation Energy comes from the sodium-ion battery research team led by Professor Ma Zifeng at Shanghai Jiao Tong University. The second category includes companies extending their existing lithium-ion battery technology to sodium-ion batteries, such as CATL (Contemporary Amperex Technology Co., Ltd.).

According to incomplete statistics, HiNa Battery launched a 1GWh sodium-ion battery production line in July 2022, Huayang Group launched a 1GWh sodium-ion cell production line in September 2022, and Transimage Technology started production of 4.5GWh sodium-ion batteries in October 2022. Additionally, Do-Fluoride Chemicals has a production capacity of approximately 1,000 tons of sodium hexafluorophosphate, and its subsidiary, Jiaozuo New Energy, has a production capacity of 1GWh for sodium-ion batteries.

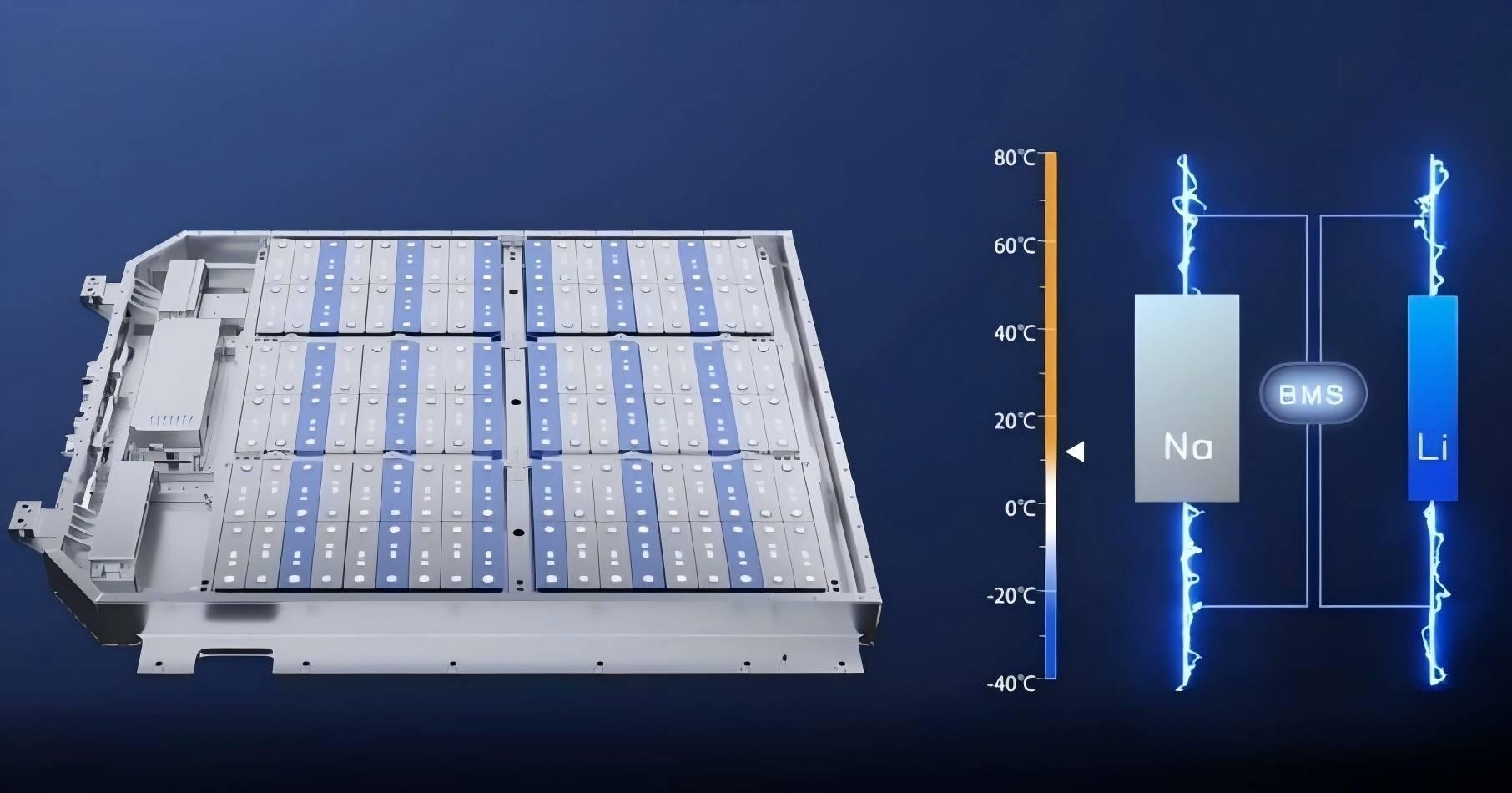

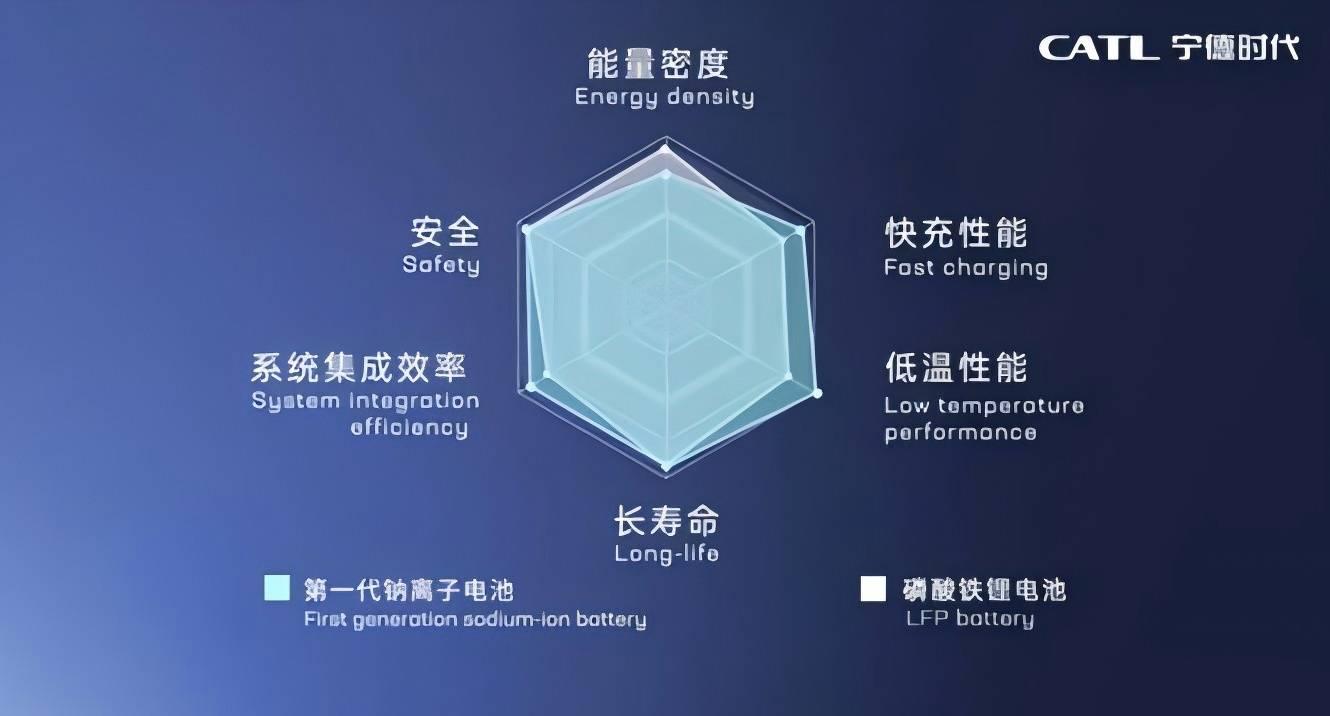

On July 29, 2021, CATL released its first-generation sodium-ion battery, which utilizes a Prussian blue and/or layered metal oxide/hard carbon system, designed to complement lithium-ion batteries. Sodium-ion and lithium iron phosphate batteries are integrated into the same battery system, managed uniformly by a BMS (Battery Management System) to achieve a balance of energy density and low-temperature performance.

According to information from the press conference, CATL's sodium-ion battery cells have an energy density of 160Wh/kg, which is slightly lower than that of current lithium iron phosphate batteries. At room temperature, the battery can be charged to more than 80% within 15 minutes and has a discharge retention rate of over 90% in low-temperature environments as cold as -20°C. The system integration efficiency (pack efficiency) can reach over 80%.

According to previous research information, CATL (Contemporary Amperex Technology Co., Ltd.) is expected to achieve the industrialization of sodium-ion batteries in 2023.